|

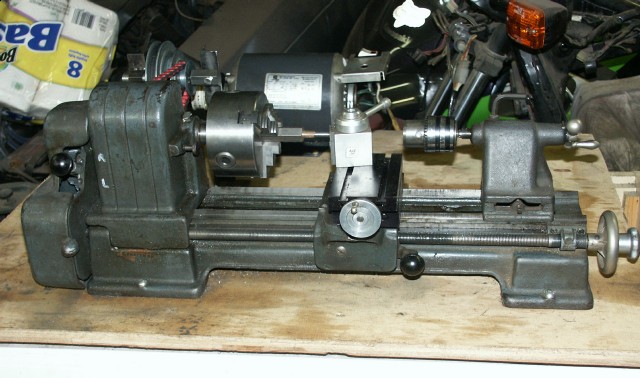

Craftsman 109.20630 Lathe, modifications and upgrades. |

Visitors:  |

For sale: Craftsman 109.20630 6x12" Lathe. --Sold--

This has been carefully restored. This is not one of those,

clean it up and paint it to sell lathes that just look nice. This

restoration was to try to get the lathe accurate an reliable.

I was not interested in a museum piece; this is something I wanted

to use.

When I received it, it had many problems. Some of the fixes

are shown on the menu above. I have spent nearly a year getting

the parts, upgrading things and fixing the problems. Finally it

is in a usable condition; in some cases better than new.

Repairs/Mods/Upgrades (cost):

- Replace bed clamps with brass for tighter fit with less drag.

- New front spindle bearing. ($40)

- New spindle made from hard tool stock (stronger than original.)

(worth $100)

- Sherline cross slide for accurate cuts with 0-0.050"

graduated dial. ($80)

- Almost brand new Sherline live center. ($40)

- A2Z Quick Change Tool Post with 4 QC tool holders: 2 regular,

boring bar holder and cutoff tool holder. ($80)

- Replaced missing gears ($50)

- Made custom counter shaft assembly to get speeds down as

to not burn spindle again.

- Replaced belt with genuine Fenner Drive Power Twist Plus

Link V-belt (not Chinese copy.) ($30)

- Replaced wrong speed motor with 1/3 HP 1750 RPM motor. ($65)

- Replaced tail stock shaft with longer one with 1/2-20 threaded

end (allows using 1/2" drill chuck close to tail stock.)

($40)

- Added heavy-duty 4" chuck. ($100)

- Spindle reworked with additional brass thrust washers for

less friction.

Lathe includes:

- Craftsman 109.20260 lathe with all original parts.

- Reprint of User Manual, Gear Chart and Parts List.

- Instructions on my changes.

- Wood stand.

- New stronger spindle and original.

- Full set of change gears, complete set with a few duplicates.

Some look never used.

- counter shaft to reduce speed and lessen wear on spindle

bearing (original bearing was shot from too fast speed especially

with a 3600 RPM motor.)

- 3/8" and 1/4" drill chucks with MT#0 mounts and

two keys. ($30)

- Original 3", 4-jaw independent chuck with key.

- Unknown make, heavy duty 4" 3-jaw self centering chuck

with key. Also has the set of reverse jaws. ($100)

- Sherline cross slide upgrade with spare T-nuts. ($80)

- Original compound slide with brass Gibbs and the original

24-TPI lead screw and a 20-TPI lead screw (20 TPI allows 0.050"/per

rotation of dial.)

- Upgraded brass carriage clamps and the originals.

- A2Z quick-change tool post with adapters for both the Sherline

and original cross slides. ($80)

- 10 Carbide 5/16" tool bits, used ($16)

- Several used 1/4 HSS bits and unused 3/16" HSS bits.

- Small 1/4" parting tool. ($7)

- 5-piece 1/4" indexable carbide tool bits. ($38)

- 4 Small boring bars. ($20)

- Brand new 1/2" x 1/16" parting tool. Made in Germany.

($10)

- 4 center drill bits, used unknown condition. ($5)

- Brand new, unopened bottles of Mobil synthetic Spindle and

Way oil. ($15)

- Additional Link belt, approximately 2 feet.

- Toolbox

- Two lengths of 9/16" 12L14 hex bar stock. 12L14 is specially

made for easy machining.

The lathe is now working better than ever. I hate to sell it

with all the work I have in it. I swore at this lathe for a long

time with its problems. Now, it is actually nice to use and works

well. But, has to go as I found a deal on a bigger

lathe and now have no room. So, has to go.

All needed fixes have been done for proper operation. Has power

feed and thread cutting capability.

The lathe itself usually sells for about $250 on ebay. That

is for an unknown condition lathe usually missing parts. Add up

all the prices shown above and you see I have nearly $700 in upgrades

and tooling.

For sale at $450, Firm. Contact me at:

Here are some notes I have on using

this lathe.

|

Craftsman 109.20260 Lathe mounted on stand.

A2Z QC tool post mounted on Sherline cross slide. I had a

Sherline lathe, it was very accurate, but just too small. This

cross slide give the accuacy on this older lathe. You lose the

compound slide capability but gain accuracy and a tighter cross

slide with more tool mounting options. The original slide can

be installed if needed for turning tapers or easier threading.

4" Heavy-duty, self-centering chuck installed. This has

improved workability immensely. The stock 4-jaw chuck is weak.

It also moves the work a bit farther out; that helps as there

is a bit of wear near the head stock (only enough to notice change

in drag on carriage.)

New 3/18" chuck in spindle.

(click on image for large view)

|

|

Counter shaft setup.

The tensioner helps keep down vibration. The Link Belt also

reduces vibration.

8-speeds easily done.

Complete Gear assembly.

|

|

Top row: Indexed Carbide Tool bits and change gears.

Bottom row: left to right:

4 QC tool holders, Parting tool, boring bar and 2 regular.

Allen wrenches for QC tool holders.

1/4" Drill chuck.

Four Chuck Keys for 1/4" chuck, 3/18" chuck, 3"

4-jaw chuck and 4" 3-jaw chuck.

T-nut to mount the A2Z tool holder on the original compound slide.

Original 3" independent chuck has been bead blasted to clean

up grime.

|

|

5-piece, 1/4" indexed carbide tool bits with extra screws

and two torx bits.

These cutters have really improved the operation of the lathe.

Since I bought the set, I have never used the other carbide or

HSS bits.

(the two missing ones are mounted in the QC holders shown

above.)

Each tool has 3 faces. Probably 5 faces are used of the 15,

one is chipped. The remaining 14 are as new.

|

|

Top Row: 10-piece 5/16" carbide tool bits. Most

are used.

Middle Row: Four center drills, Three 3/16" new

HSS cutters

Bottom Row: 1/4" HSS cutoff tool, some used 1/4"

cutters.

|

|

Top row: dead centers for tail stock and head stock.

Extra T-nuts for cross slide.

Middle Row: Sherline Live Center, brass Gibbs for original

cross slide and used brass thrust washer for spindle.

Bottom Row: Extra #10-32 screws; Original carriage

front clamps and original tail stock ram.

|

|

Top Row: Original 24-TPI cross-slide feed screw, handmade

20-TPI feed screw, bolts/nuts for compound slide.

Middle Row: Four boring bars

Bottom Row: Second set of jaws for 4" chuck .

Never used, still in packaging.

|

|

Original compound slide, base and handle.

Original rear clamp and spindle bearing

Link-Belt instructions

2 pieces of 9/16 12L14 bar stock, real nice machining steel.

|

|

Old vanity cabinet for base. Has 2 doors and 2 drawers

for storage |

|

Unopened Mobil Way and Spindle oil.

I bough this as soon as I decided to sell the lathe. Proper

oiling is critical for smooth operation and to prevent wear.

With this modern oil, the lathe should last indefinitely.

|