| Craftsman 109.20630 Lathe, modifications and upgrades. | Visitors: |

|

|

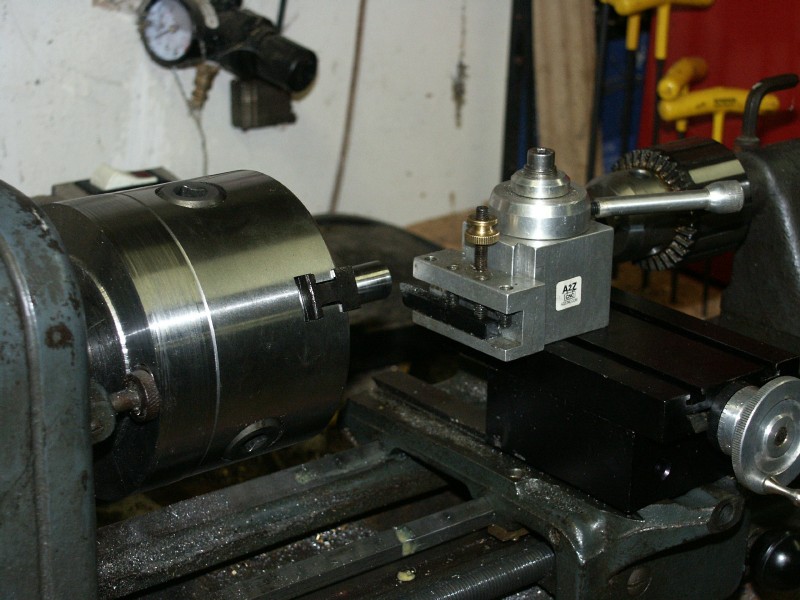

The 4" chuck is shown above. This took about 5 hours to do. Looks like the spindle is a bit bent. I mounted the back plate and it had obvious wobble. The hole was not in the exact center either. I decided to clean up the error in the adapter plate. First turned the plate outer edge round, it was slightly bigger than the chuck anyway. So, turned the entire face; that made it perpendicular to the spindle. Then turned a recess to fit the chuck to keep it centered. Then had to turn the back to clear the back gear locking pin. Turning this took a long time and had to go very slow as this is hard steel. If overworked, it hardened the steel. Then drilled the back for the mounting bolts. They had to be recessed to clear the back gear. At about an inch thick and hard steel, it took a long time to drill with multiple passes. The chuck looks to be off by about 0.004". I found there is a slight play in the step of the adapter plate that allows the chuck to mount off-center. I'll turn the step deeper so it fits better. I can live with the slight offset for now as it is better than the stock chuck. The 4" chuck is huge compared to the stock 3". It is far more durable and holds better. It is a 3-jaw, self-centering chuck. The stock chuck will be used when I need to do square stock. The chuck is huge compared to the stock, it as at least twice as long. It does have an advantage that it places the work farther out where there is less wear on the bed rails. A closer pic of the chuck and slide is hown below. |

|

|

|