| SHDesigns: Embedded Systems Design, Consulting and Developer Resources | Page hits: |

|

However, support does take up my time. If you would like to contribute to this effort, send a donation via Paypal to shenion@shdesigns.org |

| Schematic (Adobe .pdf) | Description |

| lionchg.pdf | Original version, simple charger |

| lionchrg2.pdf. | An improved version with a charge monitor LED |

| lionchg3.pdf. | Programmable from 1-3 cells and 10 to 985 ma. |

The above schematics can be viewed in Adobe PDF here:(right-click on link and select "save link as" to save.)

Update 9-27-2003: I have plot files

for a PCB. They are available in gerber and pdf. The board is

1.5" square. The files can be found in a zip file here: Plots.zip

Kevin Austin provided another CAD file for the LED version in AutoCAD dwg format: li-chg.dwg

Updated: 04-28-2003 - changed U1 pinout numbering. CAD package used non-standard pin numbers. Modified symbol to use standard pin numbering.

Update 4-27-2004: The above programmable charger has been modified. It now sets multiple voltages without adjusting the pot each time.

How to modify the circuit for different

size cells

The above circuit will charge any 2-cell * Li-Ion battery pack. Maximum current is about 650 milliamps. The circuit is designed for batteries of 900mah or higher. Note this circuit is NOT for Li-Metal batts (i.e. Duralites). Power source can be a 12v Gell cell (Power panel), or can be powered by a car's cigarette lighter. I use an old 12v DC wall transformer (800ma or more.) Radio shack sells a 12v/1amp wall DC adapter #273-1776 that will work. Supply does not need to be regulated. In fact my cheap supply outputs 17 volts with no load.

Assembly:

The entire circuit can be constructed on a small perf board 1" square or so. U1 (LM317) must have a heat sink; a small piece of aluminium will do. There are many heat sinks available. The size of the heat sink depends on the input voltage and the battery capacity. Note: the case of U1 is connected to pin 3, so the heat sink must be isolated from any other parts of the circuit. An insulator (TO-220 type) can be used to isolate the case from the heat sink if needed (i.e. bolting U1 to the case as a heat sink.) U1 should not get too hot to touch.

Adjust R4 for 8.4V out with no load.

Parts: Radio Shack part numbers given. Improved version added parts in brackets ().

| Description | RS part # | |

| U1 | LM317T adj. regulator | 276-1778 |

| Q1 (Q2) | 2N2222A NPN trans. | 276-2009 |

| R1 | 1 ohm, 1/2 watt resistor (note 1) | 271-131 |

| R2 | 2200 ohm 1/4 w, 5% res | 271-1325 |

| R3 (R5,R7) | 470 ohm 1/4 watt, 5% res | 271-1317 |

| R4 | 1K trim Pot | 271-280 |

| C1,2 | 0.1uf/50v ceramic cap | 272-135 |

| Heat Sink | 276-1368 | |

| Mounting hardware (note 2) | 276-1373 | |

| (DS1) | LED (any will do) | |

| (R6) | 47 ohm resistor. | |

| (D1) | Any 1N400x diode. |

Notes:

1. RS part is 10 watt, only size they carry in 1 ohm.

2. Required if heat sink is to be electrically isolated (recommended.)

How it works:

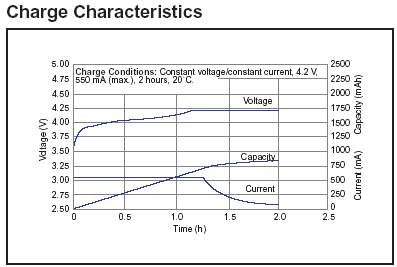

Panasonic recommends charging at a constant current of 0.7C until 4.2V/cell is reached. Then constant voltage (CV) is to be used until current drops to 0.1C. At that time, the charging should stop. The circuit follows this recommendation exactly. However it does not turn off the charge. Testing has shown that the current drops to almost zero anyway.

The circuit simplifies this by limiting the charge voltage to 8.4v. When the battery reaches 8.4v, it will no longer draw current. The charger is also current-limited. Below about 75% charge, the limit current is reached. After about 80% charge, the current decays toward 0. At about 95% charge the current drops to only a few milliamps. In theory, the battery will never finish the charge, the closer it gets, the less current it draws. If left on the charger for 2 hours or so it will reach near 100% charge. But, 95% can be reached in less than an hour in most cases (assumes discharged to 50% or so.) Panasonic's charge curve for their 830mah batts using this method is shown below:

U1 and resistors R2, R3 and R4 create a voltage regulator. This sets the termination voltage. U1 will try to maintain 1.25v across R3. The voltage divider created by R2-R4 multiply this voltage to get the desired 8.4v value.

Q1 and R1 set the current limit. The current drawn by the battery passes through R1. As the voltage across R1 approaches 0.65v, Q1 begins to turn on. Q1 then draws current from the voltage divider. This fools U1 into thinking the voltage is too high so it reduces the output.

C1 and C2 are used to reduce noise and guarantee that U1 does not become instable. Without them, U1 may oscillate.